The importance of choosing and fitting a suitable model for power production management at your plant: key considerations

Photovoltaic (PV) plants are a vital component of the renewable energy landscape, converting sunlight into electricity to support a cleaner, more sustainable future. This makes predicting their energy output accurately not just a matter of interest but also essential for optimizing performance, ensuring financial viability, and maintaining reliable operations.

Accurately calculating the expected energy production of PV plants is essential for assessing performance, identifying losses, and defining the conditions that set off alarms. Different users may have their own working definitions of expected production, depending on the goals of their individual roles, projects, or organizations (for example, contractual agreements or financial performance). Some users prefer to use the original design and financial model as a benchmark, while others rely on historical performance as a baseline.

At GreenPowerMonitor, a DNV company, we understand that there’s no one-size-fits-all solution. This is why GPM Horizon offers a range of approaches for modelling, designed to align with different operational strategies and data availability. This article explores the key considerations and the models available in GPM Horizon for power production management, to help you choose the best fit for your solar assets.

Calculating expected PV production metrics with GPM Horizon

The expected production is the cornerstone of effective performance assessments for PV plants. To calculate it, we must rely on models that provide accurate and realistic estimation of the plant’s production, based on actual operating conditions. Any inaccuracies in the calculation of the expected production impact how the monitoring system allocates losses, which affects the calculation of key performance indicators (KPIs) and the activation conditions for alarms. Therefore, accurate values for expected production are crucial not only to assess performance, but also to prevent losses and ensure optimal resource-allocation.

The two main factors that affect the calculations behind the expected production:

Data quality:

- Sensor accuracy: although often overlooked, all sensors have an inherent uncertainty, regardless of how well and regularly you carry out recalibrations.

- Maintenance: regardless of calibration, poorly maintained sensors can lead to inaccurate readings. This also makes regular maintenance crucial.

Modeling approach:

- Benchmarking strategy: this is based on technical calculations from the plant’s design, or on the plant’s historical performance. Design-based approaches are useful to evaluate losses against the model and to account for the gains or losses with respect to financial planning. Performance-based approaches focus on deviations with respect to past production, considering regular and recurring patterns in gains and losses as fundamental to the plant performance.

- Sensitivity to data inputs: by nature, physical models are sensitive to the quality of sensors, whereas machine-learning models are more resilient (as long as deviations remain consistent over time). Therefore, the decision regarding which model to use may take into consideration the quality of the sensors, together with the maintenance that they require.

GPM Horizon offers both physics-based and data-driven models, to meet all the possible needs of our users.

Calculating PV production with physics-based models

Physics-based models rely on the design of a PV plant to estimate its performance. These models are only as good as the assumptions used to build them and rely on well-calibrated sensors. Physics-based models are ideal for benchmarking against technical or financial expectations.

GPM offers different solutions for power production management, depending on the quality of the available information:

User’s design: GPM Horizon can replicate models provided by users (usually created with high-quality software, such as PVsyst or SolarFarmer), and calculate the expected production.

Strengths:

- The model can be based on a detailed 3D design of the plant.

- Ideally, the representation is as close as possible to the actual (as-built) design.

Considerations:

- The quality of the calculations depends on the modeler’s expertise.

- Unless users have in-house expertise and resources, the design is likely to come at a price.

Automatically running a model: when users do not have a model (or the model is inaccurate), GPM Horizon can automatically run a model based on the plant’s metadata.

Strengths:

- Fully automated.

- Deploys quickly and easily, with minimal manual input.

Considerations:

- Accuracy is directly tied to the quality and accuracy of the metadata.

Performance ratio (PR): GPM Horizon can use monthly PRs (from the plant’s design phase or budgets) to calculate the expected production. This is the easiest and most straightforward approach, although over-simplification makes it the least advisable.

Strengths:

- Quick and straightforward to calculate.

- Useful for high-level performance snapshots.

Considerations:

- Does not account for all of the design’s operational variables and nuances.

Calculating PV production with data-driven models

Data-driven models use historical datasets to learn how plants behave and then create a model. The result is a benchmark that you can use to compare the current performance against the plant’s historical behavior.

It is essential to clean and filter the dataset, to ensure the model learns only from periods of optimal performance, avoiding the influence of significant anomalies and underperformance that could distort the plant’s behavioral patterns. GPM Horizon has developed a proprietary algorithm that cleans and filters datasets to build machine learning models specifically designed to replicate the performance behavior of PV plants:

Strengths:

- The algorithm learns from historical performance and real operational data.

- Can accurately incorporate the effects of a 3D representation.

- As long as the sensors do not change, the algorithm learns the correlation between the sensors and the plant output, making it less sensitive to offsets in sensor calibration (as long as they do not change significantly over time).

Drawbacks:

- Patterns of over- and under-performance that are always present and cannot be cleaned will be integrated by the algorithm and assumed as correct.

Summary of models and their use cases

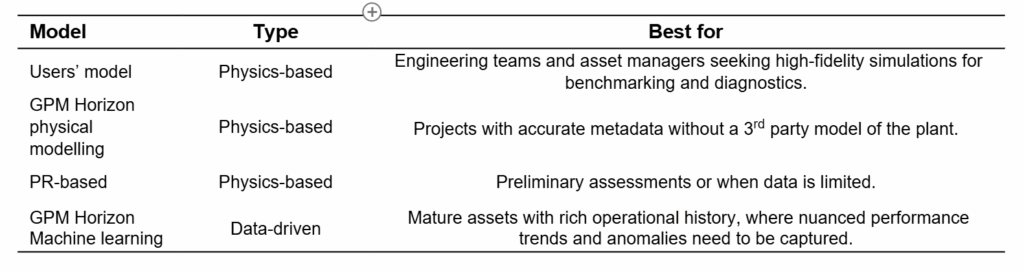

There is no one-size-fits-all solution to calculate the expected production of a PV plant – the decision to use one model over another depends on factors ranging from the needs of individual users, to the quality of the readings used to input data. GPM Horizon offers a broad set of reliable approaches to ensure that you can calculate the expected production according to your needs, for power production management at your plant, these are summarized in the table below.

Figure 1: Summary of models and their use cases

Do you want to meet us and talk to our renewable energy experts?

For more information on how GPM Horizon can help you calculate expected PV production at your plant, fill in the form to request a meeting with our renewable energy experts who will be available to answer questions, provide demonstrations, and offer insights on best practices.